Technical parts

Custom - Development - Co-design

The products developed by EXSTO for elastoforming applications are among the best performing in the world.

Their exceptional tear resistance and compression set characteristics help increase the life of your equipment.

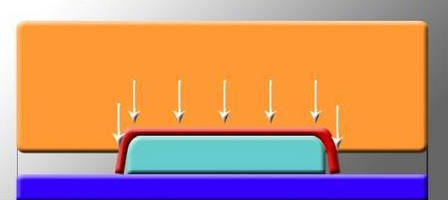

The elastoforming or Guerin or Maform process is a stamping technique, in which we use a fixed punch on which a sheet is placed.

Opposite this fixed assembly, we have a mobile container where one or more polyurethane cushions are placed.

By exerting a more or less important pressure on the container, we obtain a deformation of the cushions which come to "marry" the punch and thus give to the sheet the shape of this one.

This process makes it possible to have relatively deep tips, or even to make cutting, if the edges of the punches are sharp.

With more than 30 years of experience in the aeronautics sector, and more specifically in the elastoforming sector, EXSTO has been working for several years to offer a range of UREFLEX® polyurethane that is extremely resistant to tearing, to elongation at break and to compression set.

Our technical teams, specifically dedicated to this application sector, can come to your site for a diagnosis and make recommendations to improve the life of your cushions.

Our production capacities are among the most efficient in the world, allowing us to produce cushions in the largest possible dimensions.

Custom - Development - Co-design

One of the widest range of polyurethane products in the world.

Discover our competitive polyurethane solutions for your large dimension projects for the Energy, Aeronautics, Construction and Transport industries.