Do you really know polyurethane?

Discover the incredible potential of UREFLEX polyurethane elastomers!

Moulded polyurethane is a real alternative to plastic, metal or rubber for many applications. It is one of the most versatile and durable materials.

Its manufacturing process with relatively low tooling costs, make it a perfect alternative to more commonly used materials in a variety of applications.

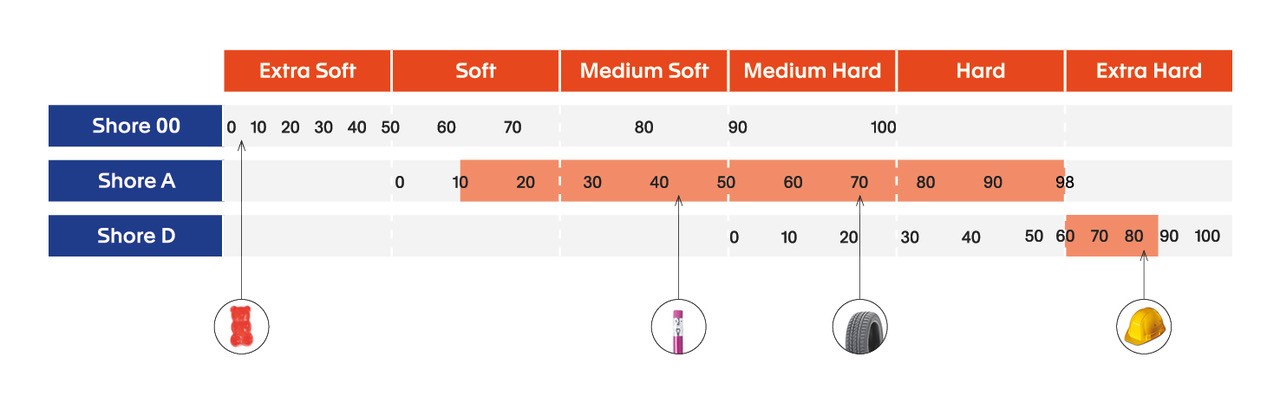

Many designers of products, engineering offices and technicians may be surprised by the physical versatility of polyurethane. Able to be as flexible as a rubber band or as rigid as certain metals, cast polyurethane is particularly suitable for parts requiring hardness and durability.

Comparative PU VS. other materials

Vs. Plastic

-

Advantages

Unlike plastic, cast polyurethane does not require high pressure tools, which speeds up lead times and reduces mould costs.

The tooling costs 1/5 less than plastic..

- Faster and more accurate prototypes.

- More durable and wear-resistant.

Vs. Metal

-

Advantages

One of the least known characteristics of polyurethane is its ability to be formulated for high rigidity, which often makes it a viable alternative to metal for valves and gears. The advanced manufacturing capability of molded polyurethane also eliminates the need for secondary operations, saving time and money in production.

-

Lighter weight.

-

Faster turnaround times and lower total costs.

-

Better corrosion resistance.

Vs. Rubber

-

Advantages

With the elastic capacity of rubber, while being measured higher on the hardness scale, polyurethane may be a good choice for some parts because of its hardness.

- Better wear resistance.

- Higher load capacity.

- Low pressure tools.

Exceptional characteritics

Elasticity

Elongation

Compression

Resilience

Damping

Rebound

An incredible hardness scale that is suitable for many applications